New educational resource helps aggregate producers, recyclers, and construction professionals select the right gravel sizes for driveways, drainage systems, and base material applications.

GrinderCrusherScreen, a leader in crushing and screening equipment sales since 1973, today announced the release of its Crushed Stone Grades Guide. The new resource provides contractors, equipment operators, and aggregate producers with detailed information on crushed stone grades, gravel sizes, and practical use cases for construction and landscaping projects.

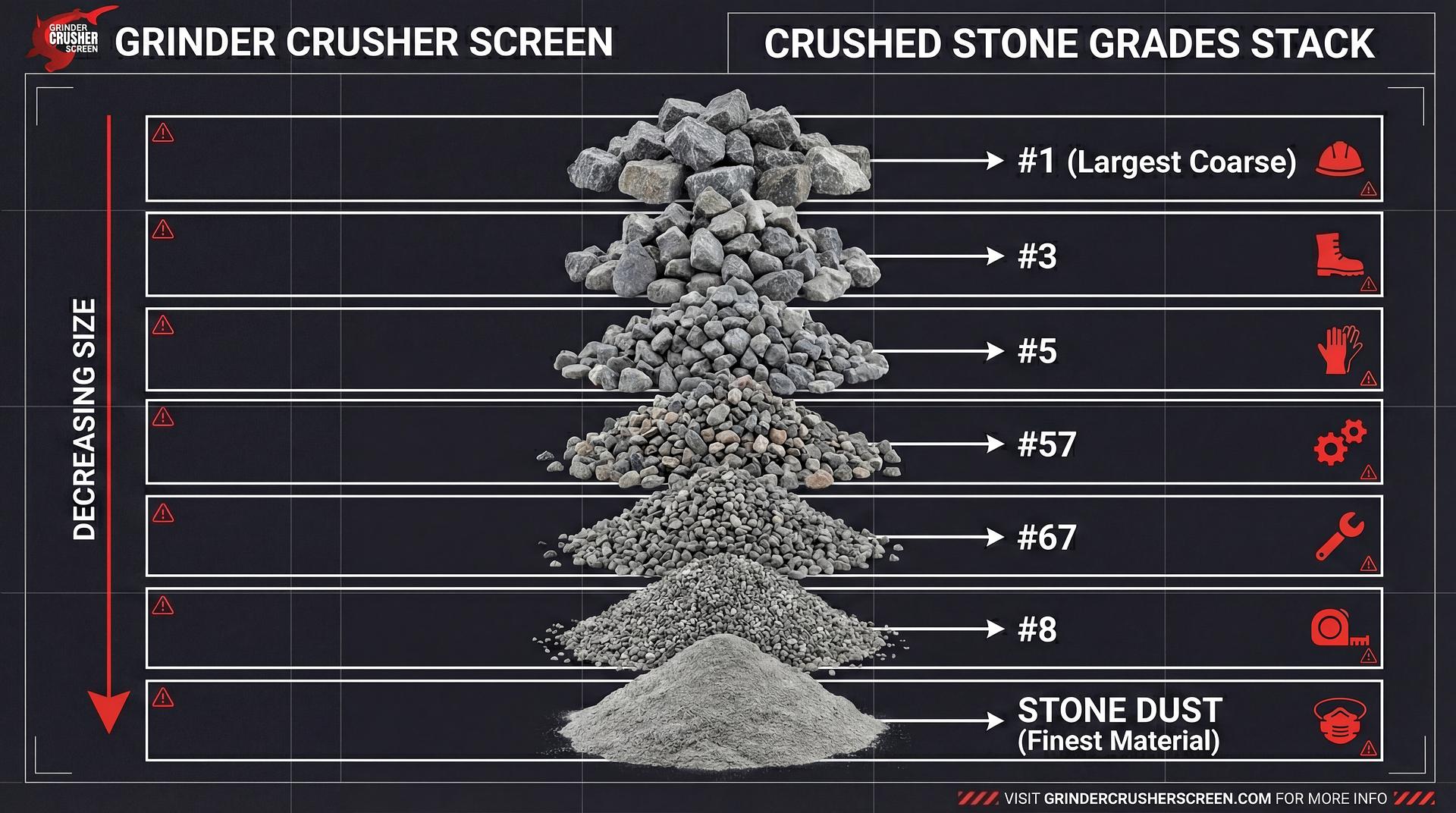

The guide addresses a common challenge in the industry. Many contractors and operators produce or purchase crushed stone, crushed gravel, and crusher run materials without fully understanding which grades work best for specific applications. This knowledge gap can lead to material waste, project delays, and costly rework. The GrinderCrusherScreen guide explains the differences between stone grades such as number 57 stone, number 67 stone, number 8 stone, and stone dust. It also covers how each grade performs in real applications including residential driveways, parking pads, French drains, and concrete base layers.

Alex Laldin, Marketing Director at GrinderCrusherScreen, explained the reasoning behind the new resource. "We talk to contractors and operators every day who run crushers and screeners but aren't always sure which finished product fits which job. They know how to make crushed stone. What they need is clear guidance on gravel sizes, stone size ranges, and where each grade belongs in the field. This guide gives them that information in one place."

The Crushed Stone Grades Guide covers material from the largest aggregate down to fine screenings. It explains number 1 stone, which ranges from two to four inches and serves erosion control and deep structural fills. It details number 3 stone for railroad ballast and highway sub-base layers. The guide walks through number 5 stone for road and paver base applications. It provides extensive coverage of number 57 stone, one of the most common grades used in driveways, drainage solutions, and slab base construction. The resource also addresses number 67 stone for tighter compaction needs, number 8 stone for concrete mixes and decorative landscaping, and number 10 stone or stone dust for paver base and joint filling.

Beyond individual grades, the guide explains crusher run and dense-grade mixes like number 411 stone. These blended products combine larger crushed stone with fine material to create superior stability and compaction for driveways and parking pads. The guide helps readers understand when to choose open-graded stone for drainage applications versus dense-grade mixes for load-bearing surfaces.

The resource also addresses a point of confusion that affects many in the industry. Crushed stone and gravel are related but not identical materials. Crushed stone features angular particles with sharp edges produced by jaw crushers, cone crushers, and impact crushers. These angular faces interlock under load and resist movement. Natural gravel consists of rounded stones formed by rivers and glacial action. The rounded particles shift more easily unless confined. The guide explains how this difference affects material selection for projects that require drainage, structural integrity, or a stable foundation.

Laldin noted that the guide reflects more than fifty years of industry experience. "GrinderCrusherScreen has been in the crushing and screening business since 1973. We have seen what works and what fails on jobsites across the country. When someone asks us about gravel for driveway projects or which stone size works for French drains, we draw on decades of hands-on knowledge. This guide puts that experience into a format anyone can use."

The Crushed Stone Grades Guide includes practical guidance for common project types. For new driveways on weak or wet soil, it recommends a deep base of number 3 or number 5 stone, an intermediate layer of number 57 stone, and a surface of number 57 or finer gravel depending on the desired finish. For parking pads and equipment yards that support heavy loads, it outlines base depths of eight to twelve inches using coarse crushed stone capped with number 57 or crusher run. For drainage systems including French drains and foundation backfill, it recommends clean number 57 stone wrapped in geotextile fabric to maintain flow paths and prevent clogging.

The guide also serves operators who produce their own aggregate using crushing and screening equipment. It explains how crusher settings and screen deck configurations determine the finished gravel sizes a plant can produce. Operators who understand the relationship between their equipment and market-ready stone grades can optimize production, reduce reprocessing, and capture more value from each ton of material. The guide connects equipment decisions to end-product specifications, helping producers deliver on-spec crushed stone, crushed gravel, and crusher run to their customers.

GrinderCrusherScreen developed the guide as part of its ongoing commitment to industry education. The company maintains an extensive library of resources covering topics from aggregate processing and conveyor systems to screener selection and crusher operation. The Crushed Stone Grades Guide joins existing resources including guides on how to crush stone, what screeners do, and how to choose between box screeners and scalping screens.

Laldin emphasized the practical value of the new guide for the company's core audience. "Our customers are contractors, recyclers, quarry operators, and equipment owners. They need information they can act on. This guide tells them which crushed stone grade to use for a driveway, which gravel sizes work for drainage, and how to produce those materials efficiently. It connects the dots between the equipment we sell and the finished products our customers deliver."

The guide addresses gravel types beyond standard crushed stone grades. It covers pea gravel for walkways and garden beds, river rock for decorative borders and water features, and specialty materials like marble chips and lava rock for landscaping projects. This coverage helps readers understand the full range of aggregate options and select the right material based on project requirements, load expectations, and aesthetic goals.

GrinderCrusherScreen serves customers across the United States and internationally. The company offers new and used crushing equipment, screening equipment, conveyors, grinders, and related machinery for aggregate production, recycling, and material processing. Its inventory includes jaw crushers, cone crushers, impact crushers, trommel screens, scalping screens, and stacking conveyors from leading manufacturers.

The Crushed Stone Grades Guide is available now through the GrinderCrusherScreen website. Contractors, operators, and aggregate producers can access the full resource at no cost. The guide provides detailed coverage of crushed stone grades, gravel size charts, and application recommendations for construction gravel, types of gravel for driveways, base material, drainage stone, and decorative aggregate.

GrinderCrusherScreen invites industry professionals to use the guide as a reference for material selection, project planning, and equipment optimization. The company welcomes questions from readers who need additional guidance on crushed stone grades, gravel sizes, or the equipment required to produce on-spec aggregate.

https://www.youtube.com/watch?v=67RB1g2_xfM

GrinderCrusherScreen has served the crushing, screening, and recycling industries since 1973. The company connects buyers and sellers of grinders, crushers, screeners, and conveyors through its equipment marketplace and provides educational resources to help operators succeed. GrinderCrusherScreen maintains relationships with leading equipment manufacturers and offers financing options for qualified buyers. The company operates from its headquarters in Smyrna, Georgia and serves customers throughout North America and beyond. For more information about GrinderCrusherScreen equipment, resources, or services, contact the company directly or visit the GrinderCrusherScreen website.

###

For more information about GrinderCrusherScreen, contact the company here:

GrinderCrusherScreen

Rick Cohen

(770) 433-2670

Sales@GrinderCrusherScreen.com

1772 Corn Rd, Smyrna, GA 30080