PICAYUNE, MS / ACCESS Newswire / June 26, 2025 / As Power Dynamics Innovations LLC (PDI) completes its work on the second of two state-of-the-art Trailing Suction Hopper Dredges (TSHDs), PDI is proud to announce its contribution to these 4,800m³ vessels constructed by Conrad Shipyard for Great Lakes Dredge & Dock Company, M/V "Galveston Island" and sister ship "Amelia Island."

These advanced dredges are built for high-capacity, shallow-draft dredging operations and feature a hopper capacity of 6,500 cubic yards (4,970 m³), with the ability to dredge up to 100 feet deep. Each vessel is powered by Tier 4 Wabtec engines totaling 16,500 horsepower.

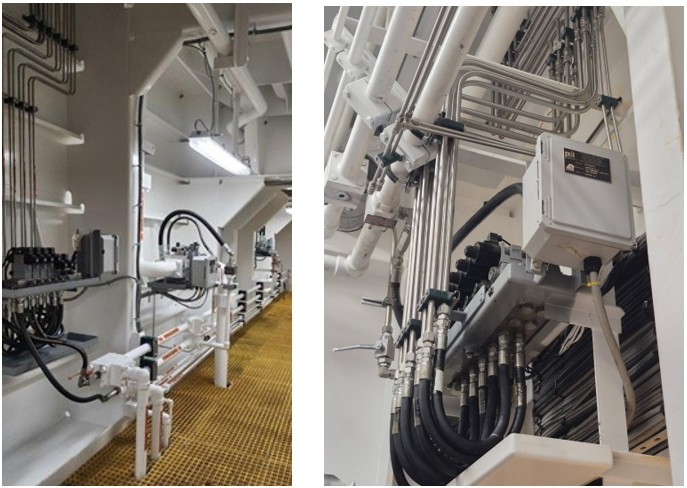

PDI collaborated closely with Conrad Shipyard and Great Lakes Dredging throughout both builds, handling the full hydraulic system installation on each vessel (excluding cranes). Across the two dredges, PDI installed approximately 4.25 miles of hydraulic piping, tubing, and hoses.

Following a comprehensive design process, PDI provided the shipyard with a precise 3D model of pipe routing, flow rates, pressures, and required pipe sizes. Over 90% of pipe spools were then prefabricated, flushed, and tested at PDI's facility in Picayune, Mississippi and delivered on-site with bulkhead penetrations and pipe supports ready for installation.

In addition to the primary hydraulic infrastructure, PDI provided pneumatic plumbing, valving, and filtration to support the vessel's swell compensation system. PDI also outfitted forty-four hydraulic manifolds to streamline control and simplify maintenance access across multiple systems.

Beyond piping, PDI supplied three hydraulic power units (HPUs) and all associated valving. These systems drive every hydraulic function on the vessel-except the deck service cranes. The main central HPU was custom-engineered by PDI to meet the vessel's demanding operational profile. All components were assembled, tested, and flushed at PDI's facility before delivery to the shipyard, ensuring clean startup and smooth integration with the onboard systems.

PDI also designed and built two custom HPUs for the drag arms' visors. The visors-hydraulically actuated gates mounted at the base of the drag arms-control the flow of dredged material into the suction pipe. By opening or closing in response to operational demands and seabed conditions, they regulate intake efficiency and prevent clogging or overloading during dredging operations.

PDI also designed and provided the swell compensation pressure vessel system, which works in conjunction with hydraulic controls to absorb fluctuations caused by sea state changes and maintain steady system pressure during dredging operations.

For the hopper's hydraulic dump doors, PDI modified the original plumbing and added a portable electric HPU to supply the cylinders in emergency conditions. This required coordination with a decentralized hydraulic system to ensure dump capability under failure scenarios.

Additionally, PDI brought its mobile pipe workshop to Conrad where hoses were fabricated and stainless-steel tubing for above-deck plumbing was bent, all on-site. PDI field personnel documented every pipe and hose in the system to ensure future replacements are quick and easy. The work was completed ahead of schedule.

PDI extends its gratitude to Great Lakes Dredge & Dock for specifying Redox pipe in the hydraulic system. The selection of Redox pipe underscores their commitment to long-term system reliability and cleanliness. The combination of PDI's prefabricated Redox spool assemblies and weldless connections minimized the risk of contamination during installation. As a result, each hydraulic system was flushed within three days, many in just one day, allowing for immediate commissioning as soon as installation was complete. This "flush-as-you-go" approach kept the process clean, efficient, and on track.

PDI is proud to have played a part in delivering these advanced dredges and appreciates the trust placed in its team by Great Lakes and Conrad Shipyard. PDI supported the full commissioning process and sea trials for the first vessel and will continue to do so for the second, ensuring seamless integration and performance of all hydraulic and pneumatic systems under real-world conditions. PDI will remain on call 24/7 throughout the service life of each vessel for any service needs or system upgrades.

To see more pictures from this project please visit our website at: https://powerdynamicsllc.com/gldd-hopper-dredges/

For additional information call (601)-229-0960 or email Sales@PowerDynamicsLLC.com

SOURCE: Power Dynamics Innovations, LLC

View the original press release on ACCESS Newswire